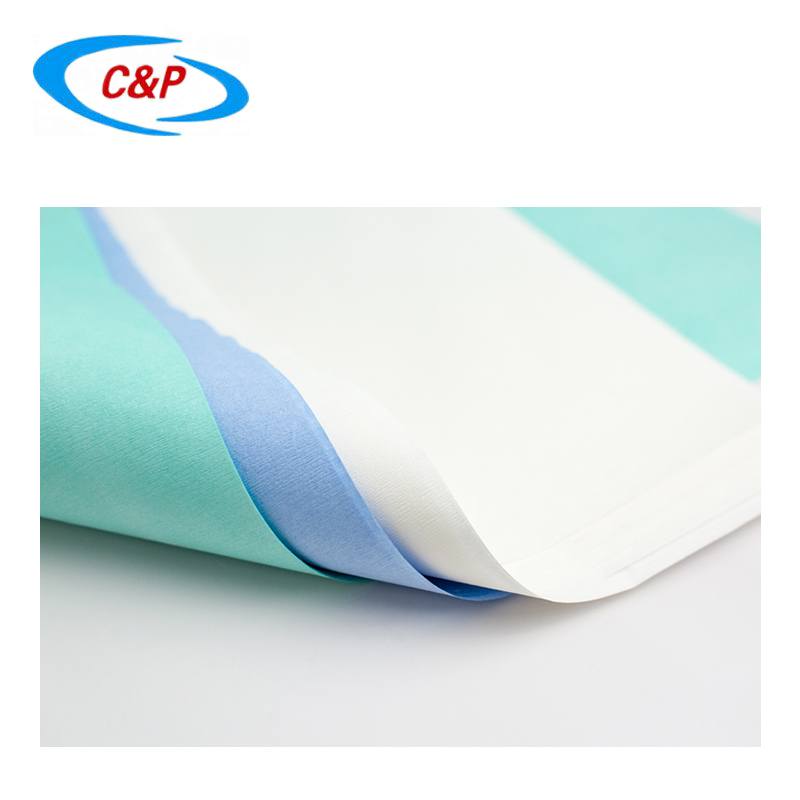

Sterilization wrapping crepe paper is a medical packaging material made of natural pure wood pulp. It is processed through a special wrinkling process to form a porous structure. It has a sterile barrier, breathability and biocompatibility. It is mainly used for the packaging of sterile items such as medical devices and surgical supplies. It is suitable for sterilization by various methods such as pressure steam sterilization, ethylene oxide sterilization and low temperature sterilization.

PRODUCT PARAMETERS

|

Name |

Sterilization Wrapping Crepe Paper |

|

Material |

Wood pulp |

|

Thickness |

20 -100gsm |

|

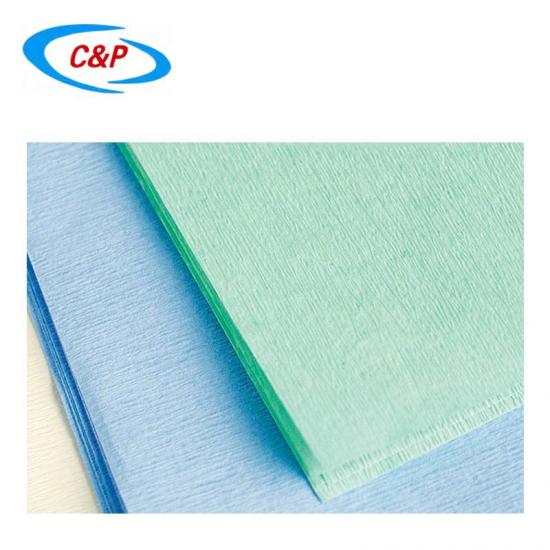

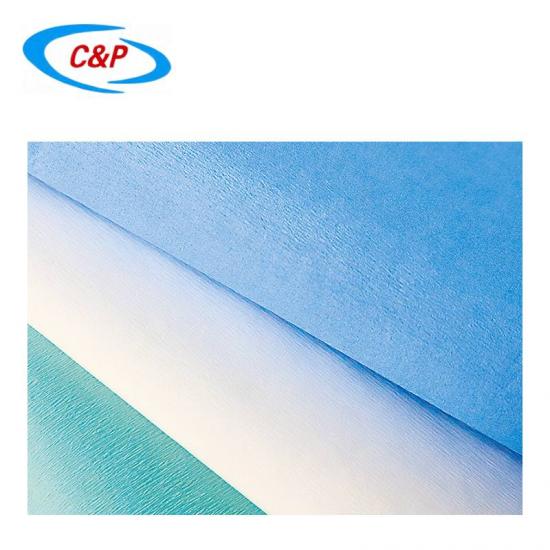

Color |

Blue, White, Green or as request |

|

Size |

As your request |

|

Packing |

1pc/sterile pack, ctn size:60x40x50cm or as request |

|

Shipping Port |

Shanghai, Ningbo |

|

OEM |

Material, Size, LOGO, Package or other specifications |

|

Quality Certification |

CE, ISO13485, EN13795 |

|

Sterile |

EO Sterile |

PRODUCT DISPLAY

FEATURES

1. Excellent antibacterial performance: The pore size of crepe paper is small, and the microbial barrier function is strong.

2. Breathability: Allows sterilization media such as steam and ethylene oxide to penetrate to ensure sterilization effect.

3. Tear resistance: The crepe paper is tear-resistant to prevent accidental punctures or tears during handling and transportation.

4. Compatibility: The crepe paper is compatible with various sterilization methods commonly used in medical institutions, such as high-pressure sterilization, ethylene oxide sterilization, and radiation sterilization.

5. Size and format: Sterilization wrapping crepe paper is available in different sizes and formats to accommodate a variety of items from small instruments to large equipment. It can be cut or folded to meet the specific needs of the packaged items.

6. Safety: Sterilization wrapping crepe paper is non-toxic and harmless.

7. Water absorption: This crepe paper usually has good water absorption performance, which can absorb and fix liquids and keep the packaged items dry.

8. Softness: The crepe paper is soft and will not damage the surface of the packaged. It also has a certain cushioning performance, which can protect the packaged items from damage.

COMPANY PROFILE

We are manufacturer and supplier of nonwoven disposable products in Hefei,China with 18 years experience of exporting. We have more than 100 employees and all products manufactured in our 3000 square meter ISO8 class cleaning room. All products with CE certification, and manufacture follow ISO13485 quality system strictly. Our main products are surgical drapes, surgical packs, surgical gowns, masks, isolation gown, equipment covers and other disposable medical products.

OUR ADVANTAGES

1. Rich production experience: With 18 years of experience in the production of medical consumables, valuable knowledge and expertise have been accumulated in this field. Enable us to better understand the needs and requirements of the industry, in order to produce high-quality products.

2. Compliance with international standards: CE, ISO13485 certificate is an internationally recognized standard for quality management in the medical device industry. This certification demonstrates that our products and processes comply with strict safety and efficacy regulatory requirements, ensuring that our product is suitable for its intended use.

3. ISO 8 clean room: ISO 8 clean rooms provide a highly controlled environment with limited particulate matter in the air. This cleanliness is crucial for the production of certain medical consumables, as it can reduce the risk of product contamination and ensure sterility.

4. Good performance: Exported to more than 20 countries.

5. Design team: We have a professional design team can do OEM&ODM.

OUR CERTIFICATE

OUR EXHIBITION

RECOMMENDED PRODUCTS