86-551-67709456 (Working time)

86-13965027700 (Nonworking time)

Medical consumables manufacturers and healthcare professionals rely on surgical sterilization wrap to maintain the sterile integrity of sterilized medical tools, implants, and consumables. This specialized packaging is a critical barrier to prevent microbial contamination, ensuring that products remain sterile from the factory workshop to the patient's bedside. In this article, we will explore the definition, process, applications, and importance of sterilization wrap, emphasizing its role in preventing infection and complying with global hygiene standards.

Definition of sterilization wrap

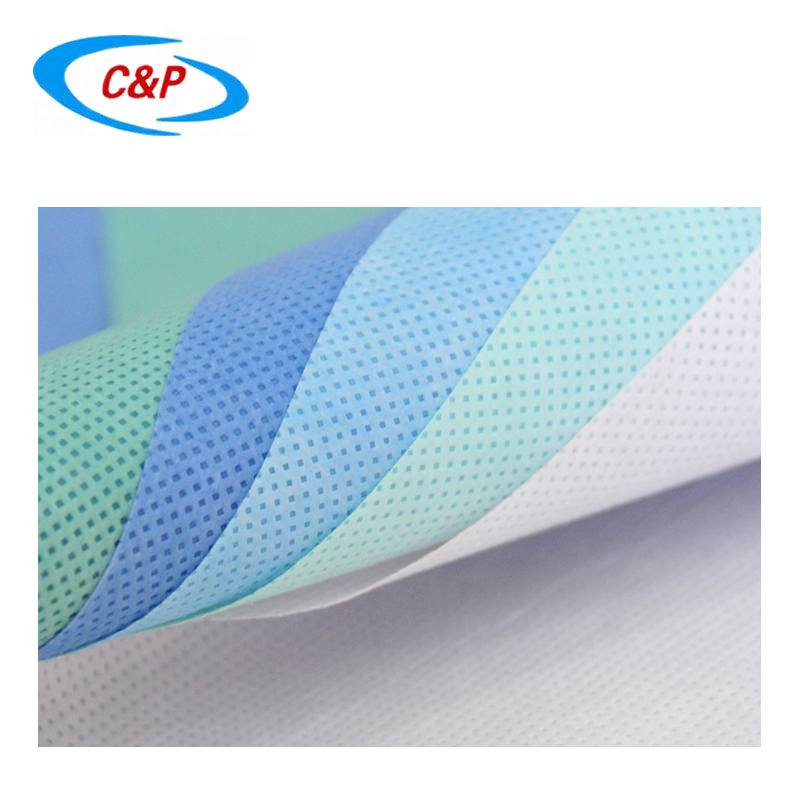

Sterilization wrap, also known as sterilization packaging, is designed specifically for the packaging of medical devices, instruments, and other medical supplies that need to be sterilized. It is made of multi-layer laminates or nonwoven fabric that can form an airtight seal to prevent bacteria, viruses, and other pathogens from penetrating the packaging. The primary function of these wraps is to create a physical or chemical barrier that protects the enclosed items from microbial contamination, ensuring that they remain sterile until they are ready for use.

Sterilization Process

Sterilization wraps are used in conjunction with various sterilization methods, such as steam sterilization, ethylene oxide sterilization, and radiation sterilization. These methods effectively eliminate all forms of microorganisms, including bacteria, viruses and spores, on the surfaces of medical devices and materials. Once sterilized, the items are carefully wrapped in sterile packaging to maintain their sterility until they are ready for use.

Applications of sterilization wrap

1. Healthcare Industry: Used to packaging medical devices, surgical instruments, pharmaceuticals, biological samples, etc.

2. Food and Beverage Industry: Use sms sterilization wrap to maintain the freshness and quality of products and extend the shelf life of products.

3. Scientific Research and Laboratory: Laboratory supplies and biological samples often require sterilization wrap to ensure the accuracy and reliability of experiments.

4. Cosmetic Industry: Sterilization wrap helps prevent cosmetic products from external contamination and maintain their quality and effectiveness.

5. Electronics Industry: Sterilization wrap can ensure that environmentally sensitive electronic products are not affected by bacteria or dust during manufacturing, transportation and installation.

The Important Role of sterilization wrap

Sterilization wrap is more than just packaging, it is a life-saving component in modern healthcare. By selecting the right materials and adhering to strict validation protocols, manufacturers and hospitals can mitigate infection risks, reduce surgical costs, and comply with global health regulations. As a trusted supplier of nonwoven medical consumables, we specialize in designing customized sterile barrier solutions based on your needs, ensuring that each package remains sterile until it is opened.

Get in touch

Scan to wechat: